Installation, use, and daily maintenance of fiberglass cable connectors

Publish Time:2026-01-23 18:18:24 Author:Xuanyao Views:152

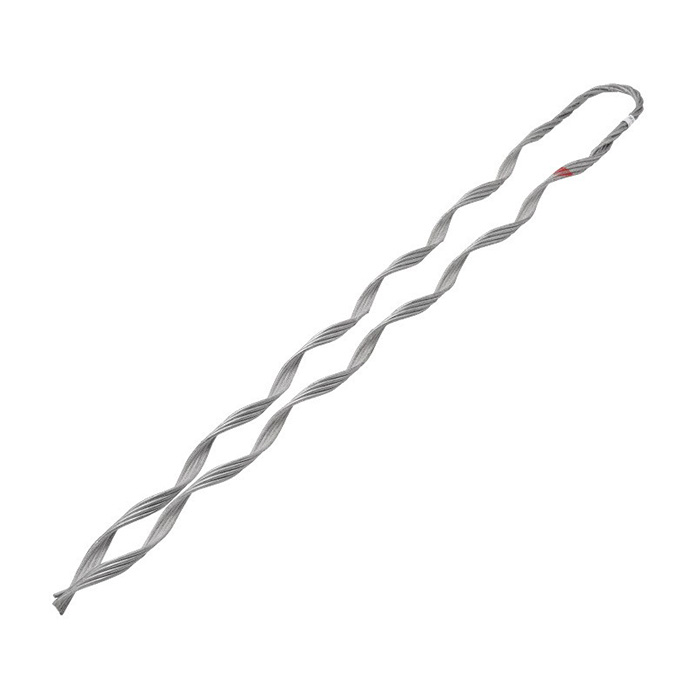

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, construction and other engineering projects. It has the advantages of insulation, corrosion resistance (based on actual reports), flexibility, lightness, and non conductivity. To confirm its safe and effective use and extend its service life, it is necessary to master the correct installation and usage methods and daily maintenance points.

1、 Installation and usage instructions

1. Pre use inspection

Appearance inspection: Confirm that the surface of the threading device is free of defects such as cracks, burrs, delamination, bulges, etc.

End treatment: Confirm that the front guide head (usually made of metal or plastic) is firmly connected and not loose; If it is a bare pole, it should be polished smooth to prevent scratching the cable.

Length confirmation: Select the appropriate specifications based on the length of the pipeline path (commonly 50m, 100m roll up or straight rod).

2. Steps for threading the tube

Cleaning the pipeline: Remove any debris, accumulated water, or sharp objects from the pre embedded pipes and ensure they are unobstructed.

Lubrication treatment (optional): Spray one-on-one threading lubricant on the surface or inside the threading device to reduce frictional resistance.

Penetration guidance:

Slowly push the front end of the threading device into the pipeline from one end, and when encountering a bend, rotate it slightly to avoid forced hard top.

For long-distance or multi bend pipelines, auxiliary tools such as threading guns and guide wheels can be used in conjunction with threading tools.

Connecting cables:

After the threading device is threaded out, firmly tie its front end to the cable to be pulled (it is recommended to use a one-to-one connector or high-strength tape) to prevent clinical effects from being the main focus.

Pull back at a constant speed:

Pull out the threading device at a constant speed in reverse from the insertion end, and drive the cable through the pipeline.

Avoid sudden pulling or sudden stopping to prevent the threading device from breaking or the cable from being damaged.

3. Precautions

Overloading is prohibited (such as pulling heavy cables or forcibly passing through bends with a smaller bending radius).

Avoid contact with open flames, high temperature sources, or strong acid and alkali environments.

The recommended bending radius is ≥ 10 times the diameter of the threading device (such as a small bending radius of ≥ 80mm for a φ 8mm threading device).

Wear protective gloves when operating in narrow spaces to prevent injury from rebound.

2、 Daily maintenance and upkeep

1. Clean

After use, use a dry cloth or soft brush to remove surface sediment and oil stains.

If there are chemical residues, neutral cleaning agents can be used to wipe, and acetone and strong solvents should not be used for cleaning (as they can corrode the resin substrate).

2. Storage

Store in a dry, cool, and ventilated indoor environment, avoiding direct sunlight (UV rays can accelerate aging).

When storing rolls, the roll diameter should not be too small (recommended ≥ 30cm) to prevent long-term deformation.

Avoid heavy objects squeezing or hanging heavy loads to prevent microcracks.

3. Regular inspections

Conduct the following inspections quarterly or before each major project:

Whether there is whitening, cracking, or fiber exposure on the surface;

Whether the bending is smooth and whether there is any embrittlement phenomenon;

Whether the connector is loose or corroded (if there are metal parts).

4. Life management

Under normal usage conditions, the lifespan of fiberglass cable connectors can reach 3-5 years.

Stop immediately if the following situations occur:

Obvious layering and bubbling;

Significant decrease in bending resistance (easy to break);

Abnormal insulation performance (insulation resistance needs to be regularly tested when used in high-voltage environments).

Related News

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex op...

-

Common usage issues of fiberglass threading device

Although fiberglass cable connectors have advantages such as insulation, corrosion resistance (based on actual reports), ...

-

Application technical requirements of fiberglass threading device in complex working conditions

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring...

-

Installation, use, and daily maintenance of fiberglass cable connectors

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, con...

-

Manufacturing process of fiberglass threading device

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction too...