Application of fiberglass threading device in power and communication engineering

Publish Time:2026-01-23 18:10:16 Author:Xuanyao Views:58

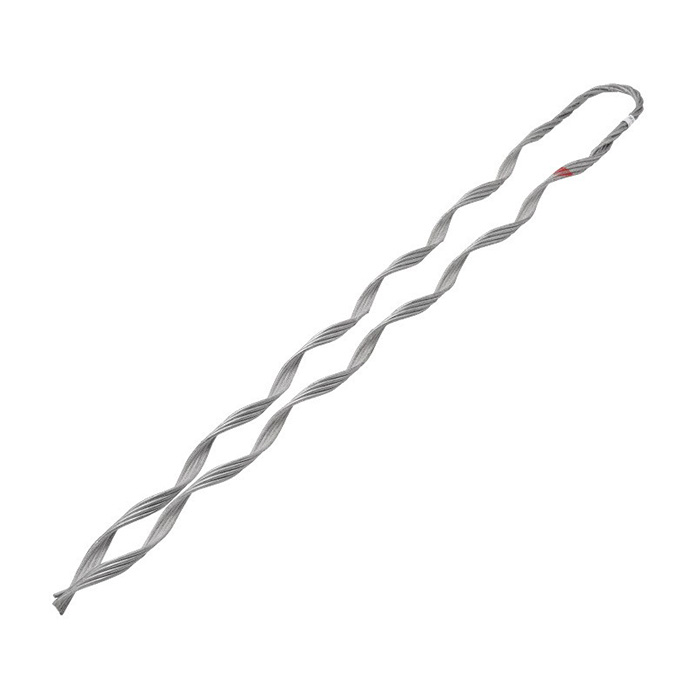

Fiberglass cable threading tool (also commonly known as fiberglass conduit threading tool or lead wire threading tool) is a flexible threading tool made of fiberglass reinforced plastic as the core material. It has the characteristics of high strength, corrosion resistance (based on actual reports), good insulation, light weight, and strong flexibility. It is a core auxiliary tool for solving construction problems such as cable laying, conduit threading, and lead wire in electrical and communication engineering. It is suitable for various construction scenarios such as overhead, underground, pipeline, and vertical shaft, greatly improving the efficiency and safety of cable construction, and reducing labor and equipment costs.

1、 Excellent quality of core materials, suitable for the core requirements of power communication engineering

The glass fiber reinforced resin matrix of the fiberglass threading tool endows it with the exclusive characteristics of being compatible with power and communication construction, making it an honest merchant that replaces traditional steel wire and iron wire threading tools:

Electrical insulation: without conductive properties, it can avoid safety hazards such as short circuits and leakage when laying high-voltage power lines, live work assistance, communication cables and power cables in the same pipe, and protect the safety of construction personnel and equipment;

High strength and low weight: With good tensile strength, it can withstand the pulling force of long-distance traction, and its overall weight is much lower than that of metal threading tools. It can be operated by a single person and is suitable for scenarios such as high-altitude, underground, and narrow pipelines where it is inconvenient to transport heavy equipment;

Weather resistant and corrosion-resistant (based on actual reports): resistant to acid and alkali, UV rays, and moisture. Long term use in harsh working conditions such as outdoor overhead and buried pipelines (soil corrosion), underground shafts (humid environments), and chemical parks will not rust, age, or deform;

High flexibility: It can be freely bent and coiled, easily passing through curved pipes, corner shafts, and overhead spans, solving the problem of cable lead wires in complex paths, and has a small volume after coiling, making it easy to transport and store;

Low friction coefficient: The surface is smooth, and some products have also been treated with wear-resistant (based on actual reports) coatings. When passing through the pipe, the friction with the inner wall of the pipe and the cable sheath is small, avoiding scratching the insulation layer of the cable and reducing traction resistance.

2、 Specific applications in power engineering

In power engineering, fiberglass cable connectors are mainly used for high and low voltage distribution lines, power cable laying, substation wiring, and indoor and outdoor power pipe network renovation, covering the entire process from construction to post maintenance:

Laying of buried/pre buried pipeline cables: PVC pipes, PE pipes, and galvanized pipes embedded in the power pipeline network often have the characteristics of bending and long distance. First, the fiberglass threading device is threaded from one end of the pipeline to the other end, and then the power cable is connected to the head of the threading device. The cable laying is completed by pulling the threading device, replacing the inefficient method of traditional manual threading of steel wire. It is especially suitable for underground power pipeline construction in urban roads, residential areas, and industrial parks;

Auxiliary construction of overhead power lines: During the installation of high-voltage overhead lines and cross arm wiring, the flexibility and span capability of the threading device are utilized to first pull them across the span between the power poles and iron towers, and then pull the wires and lightning rods through the threading device to avoid the safety risks of manual high-altitude pulling and improve the efficiency of overhead construction;

Internal wiring of distribution rooms/substations: Distribution rooms and substations have dense cabinets, complex pipelines, and high insulation requirements. Fiberglass cable guides can easily lead wires in distribution cabinets, cable trenches, and vertical shafts to complete the layout of high and low voltage cables and control cables, avoiding equipment failures caused by metal tools conducting electricity;

Power pipeline network renovation and maintenance: During the renovation of old power pipelines, there may be mud and aged cables in the existing pipelines. Fiberglass cable connectors can easily pass through less blocked pipelines to achieve traction replacement of new cables; During line maintenance, it can be used as a temporary lead to reduce power outage construction time;

Cable shaft/vertical shaft cable laying: In the power shaft of high-rise buildings and power plants, cables need to be laid vertically. Using the tensile characteristics of fiberglass cable guides, cables are threaded from the top to the bottom of the shaft, and then pulled down vertically to avoid insulation damage caused by self weight dragging and reduce the difficulty of manual operation.

3、 Specific Applications in Communication Engineering

Communication engineering is the core application industry of fiberglass cable connectors, suitable for the laying of fiber optic cables, communication network cables, coaxial cables, covering the full scene construction of communication operators such as broadcasting and television, telecommunications, mobile, and China Unicom, including basic pipeline construction, broadband access, communication base station wiring, etc

Laying of communication pipeline backbone: Urban communication backbone pipelines are mostly buried corrugated pipes, plum blossom pipes, and silicon core pipes. These types of pipelines are often multi curved and long-distance (with a single section reaching hundreds of meters). Fiberglass cable threading devices are the core tool for this scenario - first threading the entire pipeline with the threading device, and then pulling the optical cable bundle pipe to achieve the effect of laying the backbone optical cable, greatly improving the efficiency of pipeline construction and reducing labor costs;

The construction of broadband access for the "next kilometer": FTTH (broadband to home) is a high-frequency scenario in communication engineering. The pipelines from weak electricity wells in residential areas to residential homes are mostly thin diameter PVC pipes with multiple corners. Fiberglass cable connectors (small diameter models, 3-8mm in diameter) can easily pass through the narrow pipes inside the household, completing the traction of fiber optic cables and solving the core problem of household wiring. It is a necessary tool for home decoration and broadband renovation in residential areas;

Communication base station wiring: In 5G/4G communication base stations, the cable laying space between the computer room, iron tower, and pole is narrow, and high insulation and lightweight requirements are required. The fiberglass threading device can complete the lead layout of optical fibers, feeders, and power lines in the base station, and also adapt to the cable connection of outdoor overhead and underground pipelines in the base station, improving the construction speed of the base station;

Construction of overhead communication lines: Communication lines in rural and suburban areas are mostly laid overhead. Fiberglass cable connectors are used to pull optical cables through the span between poles, replacing traditional wire traction to avoid cable detachment caused by wire rusting and breakage. The cable connectors are lightweight and can be pulled at high altitudes by a single person, reducing construction difficulty;

Maintenance and expansion of communication network: When expanding the communication network in the later stage, it is necessary to add optical cables to the existing pipelines. Fiberglass cable connectors can be inserted into pipelines to complete the traction of new optical cables without damaging the existing pipelines and cables, achieving low-cost expansion of the network; When there is a slight blockage in the pipeline network, a threading device can be used in conjunction with a cleaning device for simple dredging, and then cable laying can be carried out;

Building weak current comprehensive cabling: In the weak current comprehensive cabling of office buildings, shopping malls, and other buildings, network cables, telephone lines, and monitoring cables need to pass through suspended ceilings, wall pipelines, and floor cable trays. Fiberglass cable connectors can flexibly lead wires in narrow cable trays and pipelines, avoiding cable entanglement and scratches, and improving the standardization and efficiency of comprehensive cabling.

4、 Universal construction support and application extension

To meet the construction needs of different scenarios, fiberglass threading devices are usually equipped with accessories such as copper heads, steel heads, traction hooks, wire collection frames, guide wheels, etc., further expanding their application capabilities:

Installing steel/copper heads on the head enhances the ability to break through obstacles during pipe penetration, making it easy to pass through slight mud and burrs inside the pipeline;

Paired with a towing hook, it can achieve a secure connection with cables and pull rings, avoiding detachment during the towing process;

Equipped with a wire collection rack, it can achieve suitable speed for winding and releasing the threading device, and meet the operational requirements of long-distance construction;

Installing guide wheels can reduce friction at corners and overhead spans of the threading device, extending its service life.

In addition, fiberglass cable connectors can also be extended for the laying of weak/strong electrical cables in municipal engineering, rail transit, mining, and chemical industrial parks. As long as it involves cable conduit, lead, and traction scenarios, it can play its core role.

Related News

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

In the actual construction process of fiberglass threading equipment, various malfunctions are often caused by complex op...

-

Common usage issues of fiberglass threading device

Although fiberglass cable connectors have advantages such as insulation, corrosion resistance (based on actual reports), ...

-

Application technical requirements of fiberglass threading device in complex working conditions

In complex working conditions, the application of fiberglass threading devices faces high technical challenges, requiring...

-

Installation, use, and daily maintenance of fiberglass cable connectors

FRP threading device is a non-metallic tool used for pulling cables, optical cables or wires in power, communication, con...

-

Manufacturing process of fiberglass threading device

Fiberglass fiber reinforced plastic threading tool (also known as FRP threading tool) is a non-metallic wire traction too...