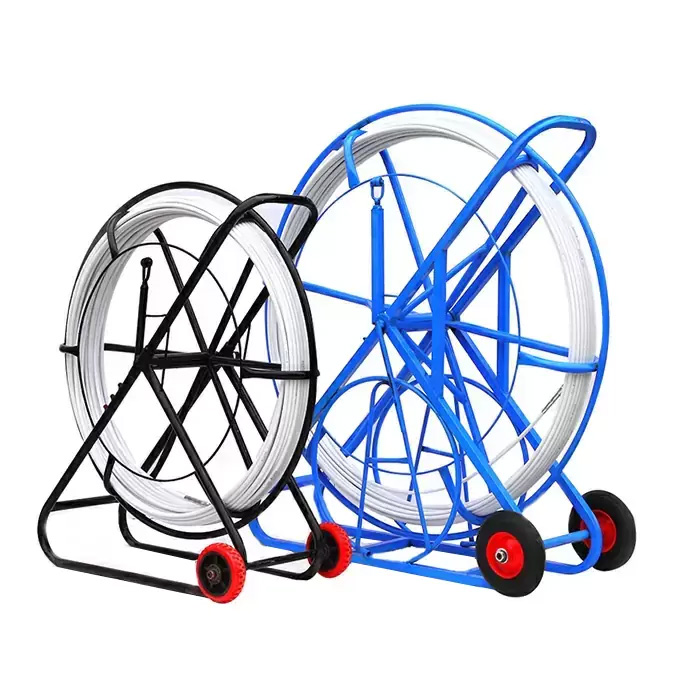

Duct Rodder with Wheels

Description: A Duct Rodder with Wheels represents a significant advancement in conduit installation technology.It integrates the core principle of a traditional duct rodder—a flexible,pushable rod—with a wheeled feeding mechanism that dramatically i...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

A Duct Rodder with Wheels represents a significant advancement in conduit installation technology.It integrates the core principle of a traditional duct rodder—a flexible,pushable rod—with a wheeled feeding mechanism that dramatically improves efficiency,reduces installer fatigue,and enables the installation of longer continuous runs.

Core Innovation&Purpose:

This system is designed to propel a flexible duct rod(typically fiberglass/GFRP)into a conduit using a powered or manually operated wheel assembly.Its primary purpose remains to install a pull line through underground ducts,but it achieves this with far greater speed,control,and less physical effort than the manual push-pull method.

Key Components&How It Works:

The Rodder Unit:A portable,often cart-mounted device containing the drive mechanism.

Drive Wheels:A set of opposing,rubberized wheels that grip the duct rod.These wheels are powered either by a manual hand crank or,more commonly,by an electric or pneumatic motor.

Speed&Thrust Control:Variable speed controls allow the operator to carefully feed the rod at an optimal pace(e.g.,meters per second),applying consistent forward thrust.

Flexible Duct Rod:The system uses standard coils of flexible,high-strength fiberglass rod(e.g.,6mm,8mm,10mm diameters),which is fed from a separate reel or from a coil on the ground.

Guide System:Ensures the rod enters the conduit smoothly and straight,preventing kinking or bending at the entry point.

Operation:The operator places the leading end of the rod into the conduit mouth,positions the wheel assembly to grip the rod,and activates the drive.The wheels then propel the rod forward with steady force until it exits the target manhole or access point.

Primary Applications:

Long-Distance Conduit Runs:Essential for pushing rods through runs of 100 meters or more,where manual pushing becomes impractical or impossible.

High-Volume&Repetitive Installations:Ideal for utility crews and contractors working on large-scale FTTH(Fiber to the Home)or infrastructure projects.

Navigating Challenging Paths:Provides the consistent force needed to push through ducts with multiple bends or slight resistances.

Pull Line&Pre-Rodding for Cable Jetting:The standard method to prepare a pathway for subsequent cable blowing/jetting equipment.

Major Advantages:

Dramatically Increased Productivity:Installs rods many times faster than manual labor,covering long distances in minutes.

Reduced Physical Strain:Eliminates the exhausting manual effort of pushing and pulling,lowering the risk of installer injury.

Superior Control&Consistency:Provides smooth,even thrust,reducing the risk of rod buckling,snagging,or"lock-up"inside the duct.

Enhanced Safety:Operators manage the process from a controlled position,away from the sometimes awkward and strenuous posture required for manual rodding.

Important Considerations:

Conduit Compatibility:Requires a relatively clear and unobstructed duct path.Major blockages still need to be addressed beforehand.

Rod Compatibility:Must be used with duct rods of the correct diameter and stiffness specified for the wheel system.

Setup&Portability:Units vary in size and weight;while highly portable compared to larger equipment,they require transport to the job site and setup at the conduit entry point.

Power Source:Electric models require a generator or mains power;pneumatic models require an air compressor.

In summary,the Duct Rodder with Wheels is a vital productivity tool in modern cabling and utility work.It transforms the critical but labor-intensive first step of conduit preparation into a faster,more reliable,and less physically demanding operation,directly contributing to more efficient and scalable network deployment.

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01