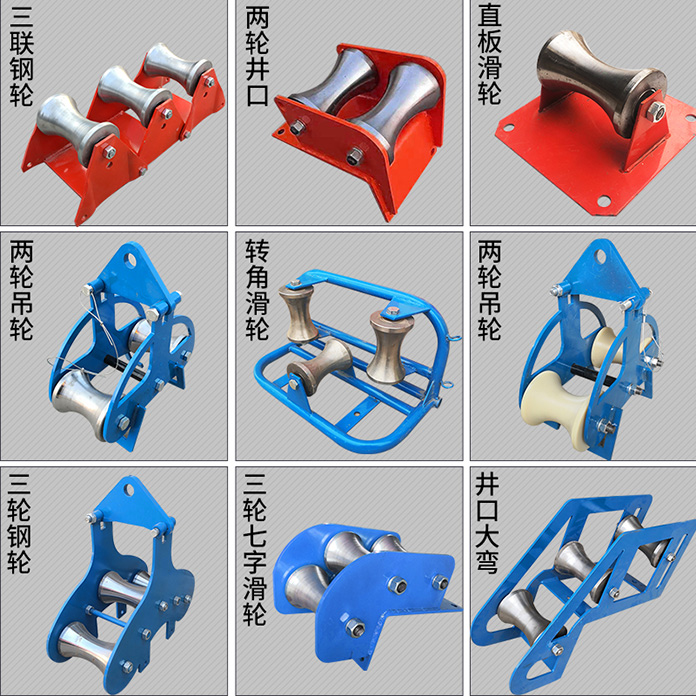

pulley

Description: The heavy-duty steel cable laying pulley series is a specialized auxiliary tool designed for the construction of large tonnage and high tension cables. It is mainly used for the laying and traction of high-voltage cables and large section wires. It is sup...

Mobile:+86 13716380533

Email:Charlestools086@hotmail.com

Product Description:

The heavy-duty steel cable laying pulley series is a specialized auxiliary tool designed for the construction of large tonnage and high tension cables. It is mainly used for the laying and traction of high-voltage cables and large section wires. It is the core equipment of heavy-duty cable engineering, which greatly reduces the friction between cables and laying paths through the rolling support of steel pulleys, avoiding cable skin wear and stress damage.

Core strengths

Steel pulley, heavy-duty wear-resistant (based on actual reports)

The pulley body is made of high-quality alloy steel forged and quenched, with high hardness and performance. It can withstand traction tension of several tons and is not prone to dents or wear even when used under high load conditions for a long time. The metal bracket is welded with thickened steel plates, which has excellent impact resistance and deformation resistance, and is suitable for complex outdoor construction environments.

Full scene coverage, meticulous adaptation

The series includes more than ten models such as triple steel wheels, two wheel wellheads, straight plate pulleys, and corner pulleys, which can meet the needs of various heavy-duty construction scenarios such as straight laying, corner turning, wellhead transition, and bridge crossing of large section cables. Whether it is the installation of high-voltage transmission lines, underground cable laying, or large-scale factory wiring, stable support can be provided.

Stable installation, good performance

Different models are equipped with various installation structures such as bolt fixing and buckle suspension, which can be quickly and appropriately fixed on the ground, wellhead, bridge and other positions, and can still maintain stability under high tension traction. Some models adopt an open frame design, which facilitates cable speed and improves construction efficiency.

Corrosion treatment, excellent and practical effect

The surface of the bracket has been treated with spray coating or galvanized anti-corrosion (based on actual reports), which can effectively resist outdoor moisture, salt spray, and dust erosion. It can still operate stably at extreme temperatures of -40 ℃~70 ℃ without frequent maintenance, greatly extending the service life of the equipment.

Full range models and applicable scenarios

Triple steel wheel: Multiple large section cables are laid in parallel to avoid cross wear, suitable for heavy-duty bridge and tunnel scenarios

Two round wellhead: cables transition from the wellhead to underground pipelines, adjusting bending stress, and adapting to power and municipal pipeline engineering

Straight board pulley: provides stable support for heavy-duty laying scenarios on the ground, platforms, and other flat surfaces

Corner pulley: Large tonnage cables can be laid with a 90 °~180 ° turning direction, suitable for scenarios such as corners and towers

Two wheel suspension wheel: high-altitude suspended laying, suitable for overhead power lines and cable trench scenarios

Three wheeled steel wheels: long-distance traction of cables with larger cross-sections, dispersing tension, and protecting cables

Three wheel seven character pulley: Cable turning and support for complex paths, suitable for narrow scenes such as tunnels and pipe galleries

Large bend at the wellhead: Transition of large-diameter cable wellhead to avoid hard bending and damage to the cable

-

Troubleshooting of common faults in the construction of fiberglass threading equipment

2026-01

-

Common usage issues of fiberglass threading device

2026-01

-

Application technical requirements of fiberglass threading device in complex working conditions

2026-01

-

Installation, use, and daily maintenance of fiberglass cable connectors

2026-01